Get the most out of your machine's data.

Machine monitoring, quality control and closed-loop industrial process optimization powered by real-time data analytics and Edge-AI.

- Predictive Maintenance

- Optimization

- IoT

- Quality Control

- Automation

- Predictive Maintenance

- Optimization

- IoT

- Quality Control

- Automation

- Predictive Maintenance

- Optimization

- IoT

- Quality Control

- Automation

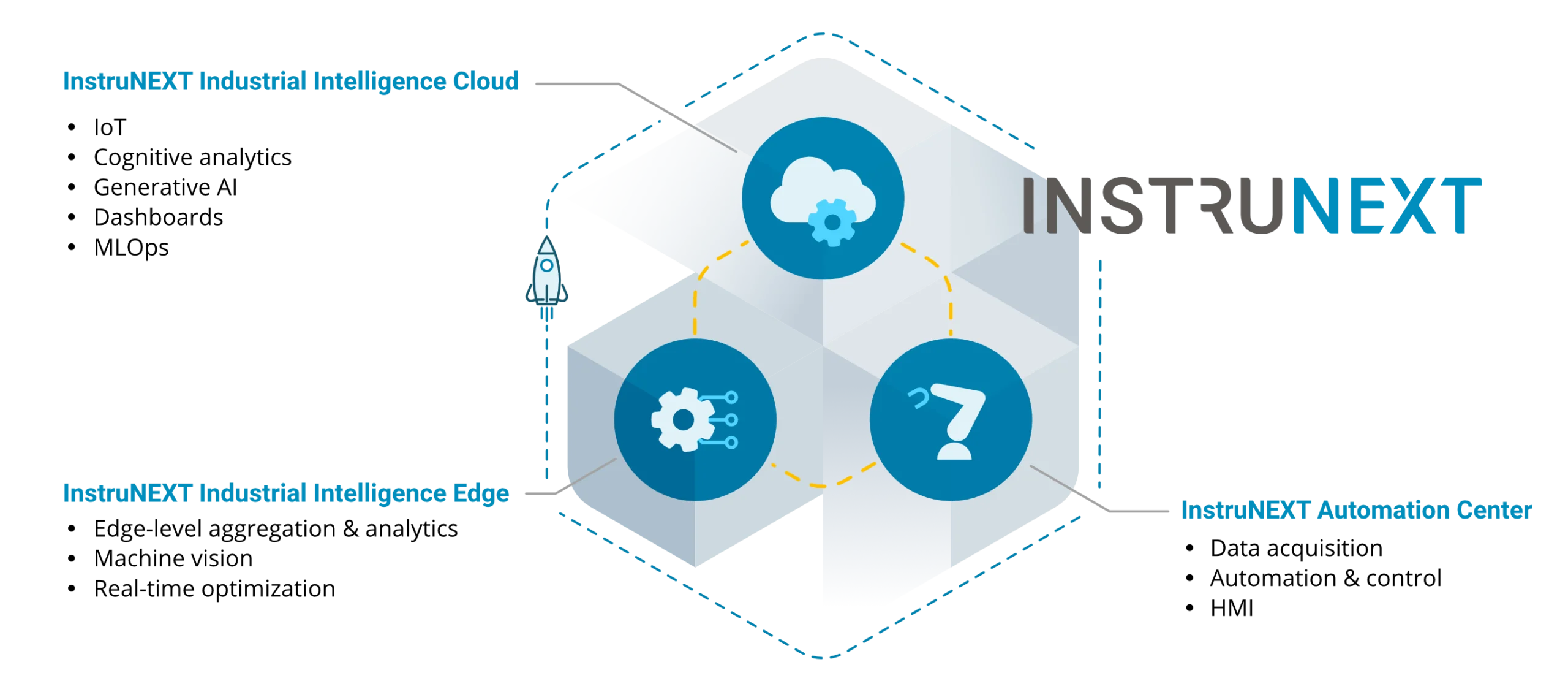

The InstruNEXT Platform at a Glance

The InstruNEXT software platform enables you to easily integrate real-time data analytics and artificial intelligence into your machine’s automation and to realize smart manufacturing solutions with edge, cloud, or hybrid architecture.

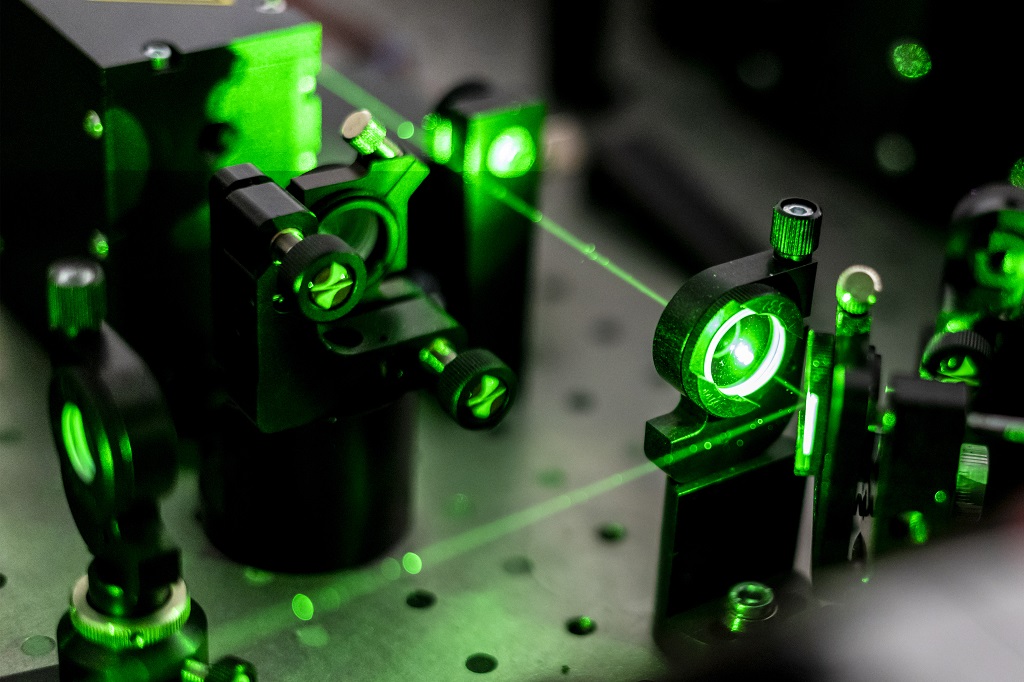

InstruNEXT Industrial Intelligence Edge

Collect and analyze data to optimize processes, inspect product quality and monitor the machine condition in real-time to gain new and valuable insights. Benefit from high data security and low latencies at the edge-level. Features like AI-powered machine vision and anomaly detection help you to identify problems earlier and to respond faster.

- Edge-AI

- Real-time

- Machine Vision

- Data Extraction

InstruNEXT Industrial Intelligence Cloud

Analyze IoT data, predict system behavior and combine data across multiple domains to eliminate data silos. Bundle up all important parameters in one place. Move resource-heavy tasks to the cloud to relieve your local resources. Scale your system fast and easy by adding new resources on demand.

- IoT

- MLOps

- Digital Twin

- Cognitive Analytics

InstruNEXT Automation Center

Easily automate and control test stands and experimental setups. Eliminate time consuming tasks and increase reliability and traceability of your tests and results. Accelerate your analysis with AI-powered features and reduce development times.

- DAQ

- Control

- HMI

- Test Stand

Applications

With the InstruNEXT platform you receive a comprehensive tool to approach various topics. Equip your machines with forward-thinking data analysis to control your processes effectively. Decrease down-times, reduce the number of rejects or improve resource efficiency. Our platform is capable to tackle many aspects in one holistic and user-friendly solution.

Predictive Maintenance

Monitor your machine’s condition precisely and detect anomalies early. Avoid expensive down-times and plan maintenance schedules more efficiently.

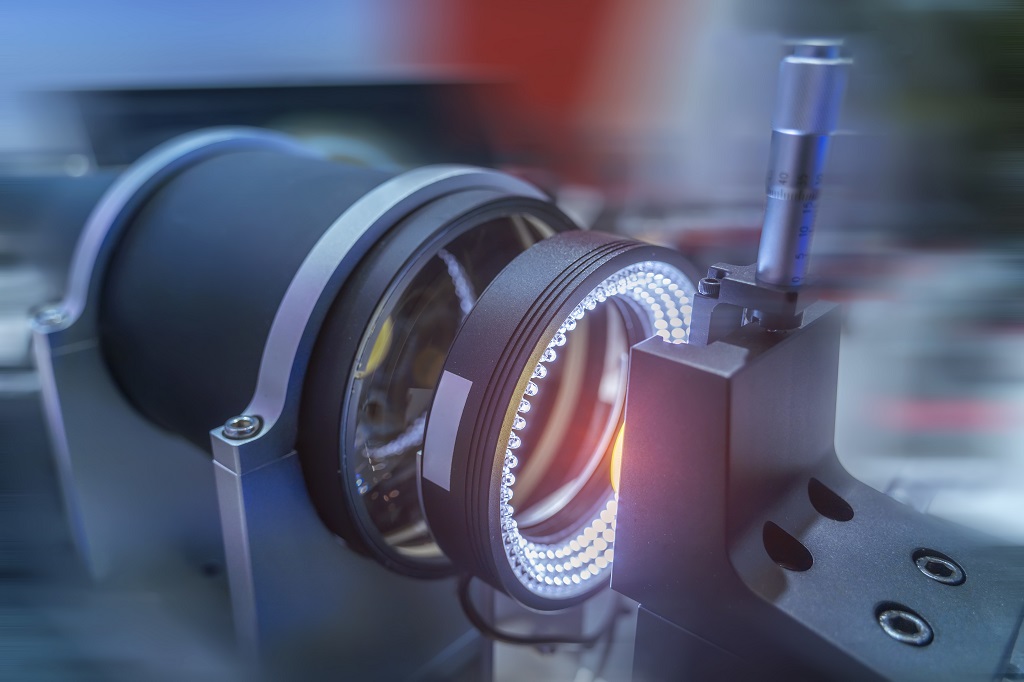

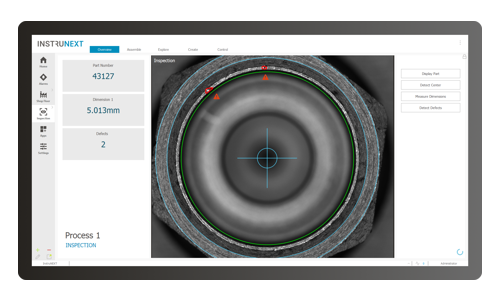

Quality Control

Use AI-based image processing to detect quality issues and reduce rejects. Correlate variations of process and machine data to quickly identify the root-cause of a problem.

Process Optimization

Tune process parameters automatically to optimize target KPIs. Improve throughput and reduce energy consumption.

Test Stand Automation

Acquire data from measurement equipment and create automated test or inspection sequences. Visualize data and improve traceability.

Why InstruNEXT?

Make your machines future-proof and strengthen your competitiveness in a rapidly evolving industrial landscape. Our AI-supported data analysis and data visualization can be customized specifically for your needs and increase your machine’s value.

Multi-Domain Data

Bring image data, sensor data, environmental data and process parameters together to gain new and valuable insights. This comprehensive approach increases your knowledge about underlying interactions and uncovers overlooked dependencies of your processes. It enables you to optimize them more efficiently and detect issues earlier.

Easy Integration

Combine our edge, cloud and hybrid building blocks as you need it. All data from real-time to historical can be easily transferred and processed. Standardized interfaces facilitate a hassle-free connection of new software and hardware components. The modularity makes the InstruNEXT platform also an excellent solution for retrofitting without extensive overhauls.

Customization Flexibility

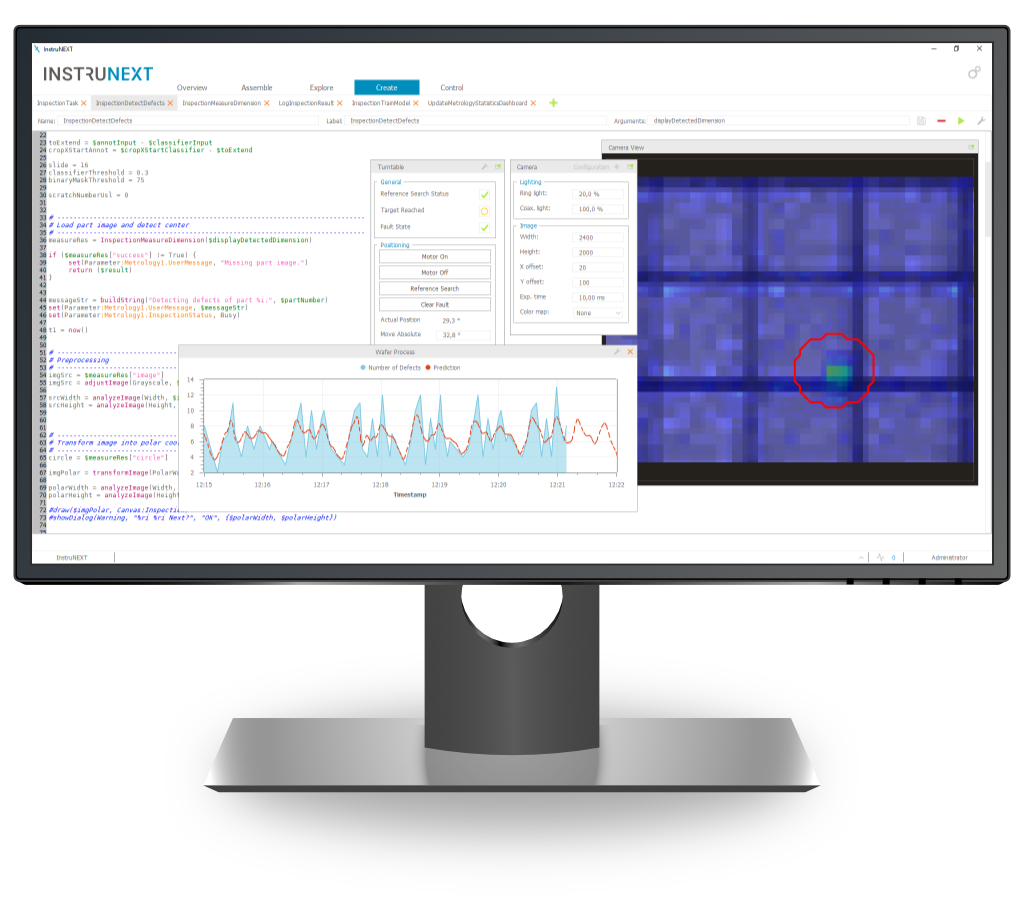

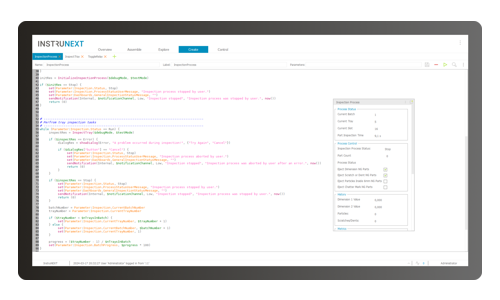

Create custom and intuitive dashboards effortlessly and adjust them when requirements change. Add new elements via drag & drop to monitor your important KPIs. With our low-code scripting language you can further specialize your data analysis and visualizations without any advanced programming knowledge.

Closed-Loop Operation

Results and predictions obtained by the InstruNEXT platform can be directly fed back in your control system in real-time. Your machines will not only respond to deviations but also learn and refine their processes to autonomously make well informed decisions beyond traditional automation capabilities.

Take the next step into the future of smart industrial automation.

Feature Highlights

The InstruNEXT platform gathers a wide variety of powerful features all in one place. This saves you from the hassle of managing and exchanging data across multiple isolated solutions. You can easily combine features as needed, ensuring seamless integration across different domains and allowing to exploit the full potential of your data.

Data Analytics & Machine Learning

The InstruNEXT platform includes tools and customizable building blocks to access various sources of live and historical data, such as sensors, control systems, log-files and databases. You can use a wide range of functions to analyze such data and to create tailored models for process monitoring, anomaly detection, forecasting, optimization and root-cause analysis. By utilizing the TensorFlow machine learning framework, you gain access to a broad range of deep learning models. You can import, manage and utilize neural networks for images, time-series and other types of data, individually designed for your application.

TensorFlow, the TensorFlow logo and any related marks are trademarks of Google Inc.

- Failure Prediction

- Anomaly Detection

- Optimization

- Root-cause Analysis

- AI

Intelligent Image Processing

You have access to various image processing functions including conventional machine vision and deep learning models to realize applications for position localization, defect detection, surface inspection, dimension measurement, object classification and vision-based process monitoring. The image processing can operate on live camera data and stored images. You can develop, train and deploy your own image models.

- Deep Learning

- Inspection

- Quality Control

- Visual Monitoring

Process Control & Automation

The InstruNEXT platform includes building blocks for interfacing of automation components such as sensors, actuators and PLCs. Using the integrated scripting language, you can realize process sequences and automations, which invoke data analytics, image processing and machine learning algorithms seamlessly. You can imediately feed back analysis results into your process to turn data-driven insights into real-time actions.

- Scripting

- Actuators

- Recipes

- Interface

- Sensors

Data Visualization & HMI

You can combine traditional HMI features, such as dials, pushbuttons, switches and indicators, with customizable data visualization tools. This allows you to integrate dashboards and control panels seamlessly with AI-driven insights, providing users with process control capabilities and powerful analytics in a modern and intuitive UI, all secured by an integrated access and rights management.

- Dashboards

- Widgets

- Control

- Plotting

- Indicators

Advantages for Your Industry

The versatile and highly adaptable design of the InstruNEXT platform facilitates its application across various industries. Whether you’re in manufacturing, machinery, research, or an integrator, you can quickly implement tailored solutions, solving your unique challenge.

Manufacturing

Utilize existing data from your machines more efficiently. Retrofit data-driven functionality and monitoring to optimize your production. Reduce scrap, increase equipment availability and decrease operational costs.

Machine Builders

Augment your machines with new data-driven capabilities which seamlessly integrate with your systems. Offer your customers additional value, boost your competitive strength and break ground for new digital business models.

System Integrators

Use powerful real-time data analytics and artificial intelligence in your projects and offer your customers innovative turn-key solutions that can be taylored specifically to their needs. Benefit from attractive conditions as a distribution partner.

Research & Development

Control and monitor your setups and test benches. Automate tedious and repetitive tasks. Integrate artificial intelligence in your test planning and evaluation to reduce the number of experiments. Increase traceability and improve repeatability.

Success Stories

Schedule your free personalized demo today.

Are you ready to take the next step? During a free product demo with our experts, we will guide you through the capabilities and features of the InstruNEXT platform.